Marieholm Tunnel Gothenburg - 'Immersed Tunnel Design' Project

MH Poly contributed to the realization and immersion of the Marieholm Tunnel in Gothenburg, Sweden, from 2013 to 2018. They were involved in various phases, starting from the tendering process to the immersion of the third and final tunnel section.

Project Description

The Marieholm Tunnel is a part of the broader Marieholm Connection Project, aiming to enhance the connection between Tingstad and Marieholm through the construction of both a bridge and an immersed tunnel. The immersed tunnel spans 500 meters and consists of three sections and a cut-and-cover portion. It is designed to accommodate three traffic lanes in each direction, with a total capacity of 90,000 vehicles per day. Construction work on the tunnel commenced in 2014, with completion expected in 2020.

MH Poly's involvement began earlier when they participated in a consortium during the project's tender phase in 2013. During this phase, MH Poly provided input on various methods of tunnel immersion. After winning the project bid, MH Poly's focus shifted to designing the temporary structures needed to facilitate the immersion of the three tunnel sections. Additionally, they considered how these temporary structures would interact with permanent constructions. Throughout the immersion process, MH Poly also provided on-site guidance and support to the consortium.

Tunnel Foundation

The foundation method for the immersed elements was the conventional sand flow technique. Typically, a 1-meter-thick layer of sand is pumped from a storage area, often located on the shore, through a pipeline to the outflow points beneath the tunnel section.

To create space for the sand foundation, the tunnel element needed to be placed on temporary supports, leaving a gap between the element's underside and the ground. Normally, these temporary (secondary) supports consist of concrete foundation pads situated on the secondary side of the tunnel element. However, due to the presence of a 100mm soft clay layer, this approach wasn't feasible.

Instead, the secondary support was implemented as a piled foundation, with each support point comprising three piles. These temporary supports were constantly monitored during the immersion process. Once the sandflow procedure was finished, the tunnel element could be lowered onto the sand foundation.

Project activities

- Creation of the foundational design for submerging the tunnel components;

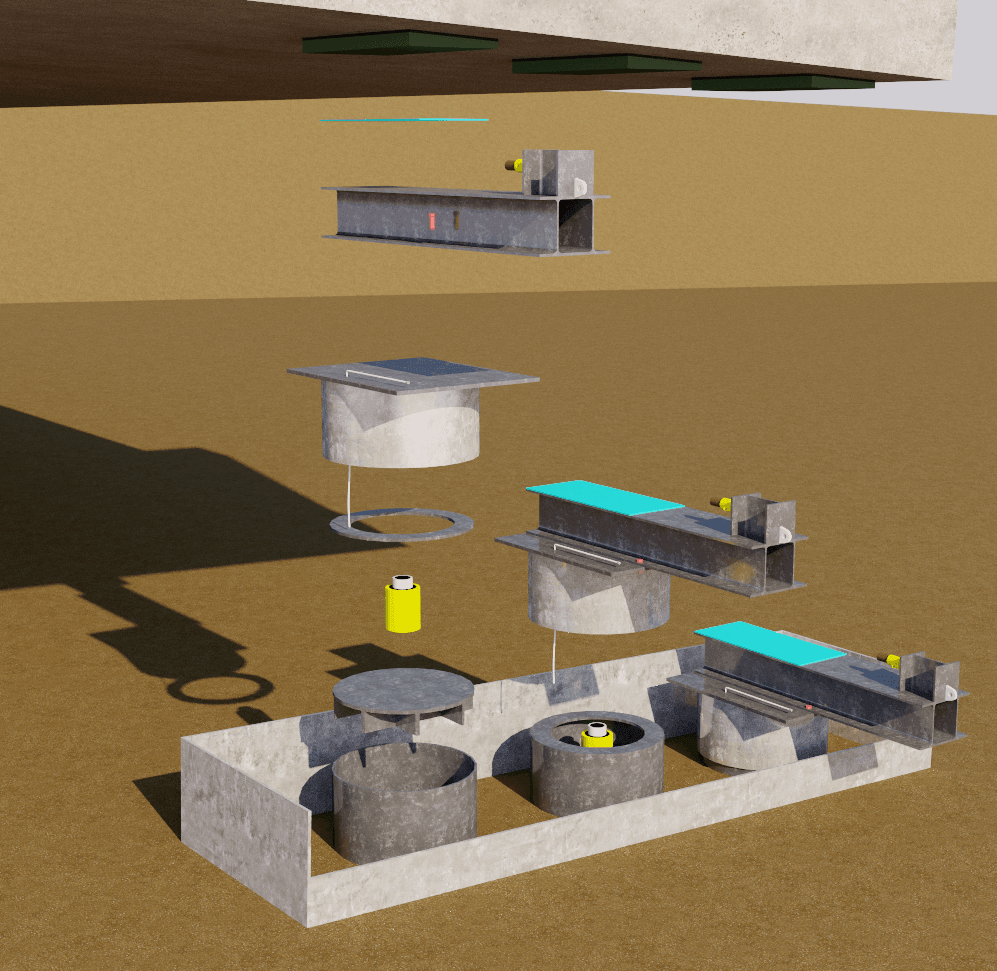

- Developing both preliminary and detailed designs for structures related to submersion, including immersion pontoons, access shafts, bulkheads, anchor points, the sandflow system, and a sealing mechanism between the immersed tunnel section and the cut-and-cover portion;

- Providing advice on the submersion process and the sequence of tunnel construction;

- Creation of visual representations for the immersed tunnel in both 2D and 3D formats;

- On-site consultation during the submersion operations.

Publication

To access the publication in the international journal 'Tunneling and Underground Space Technology incorporating Trenchless Technology Research', please click here.

Opdrachtgever

Joint Venture Marieholm (Zublin and Boskalis)

Delen