Immersion of Caissons as foundation for the Çanakkale 1915-bridge in Turkey

Project description

The “Çanakkale 1915-bridge” will become a suspension bridge which connects Lapseki and Gallipoli in Turkey. The span between the pilons of 2.023 meters will make the “Çanakkale 1915-bridge” the bridge with the longest span in the world. The completion of the bridge is planned in 2023.

Two large caissons will be the foundation of the pillars of the bridge. The caissons are 20 meters high and have a surface of 74 by 83 meters and are located at a depth of 45 meters. During a 72-hour operation, the caissons were placed on the seabed with an extreme precision of 10 mm by Strukton Immersion Projects.

Project activities

Strukton Immersion Projects (SImP) searched, together with MH Poly, for a system to relocate the two caissons from the construction dock. Hereby, MH Poly made a model of the dynamic float off and the winch operation to determine the optimal winch positions and loads for the transport of the caissons out of the building dock. The caissons are the concrete foundation on which the pillars of the bridge are built and weight approximately 66,000 tons each. After transport, the caissons were moored against a jetty in deeper water to complete their construction.

To immerse the caissons in a controlled matter, SImP and MH Poly invented together a underwater positioning system for the caissons on the seabed. This system is required to control the placement of the caissons during the immersion into the strict placement tolerances required. Later on, MH Poly worked out, in good cooperation with SImP, the drawings and the calculations of the design.

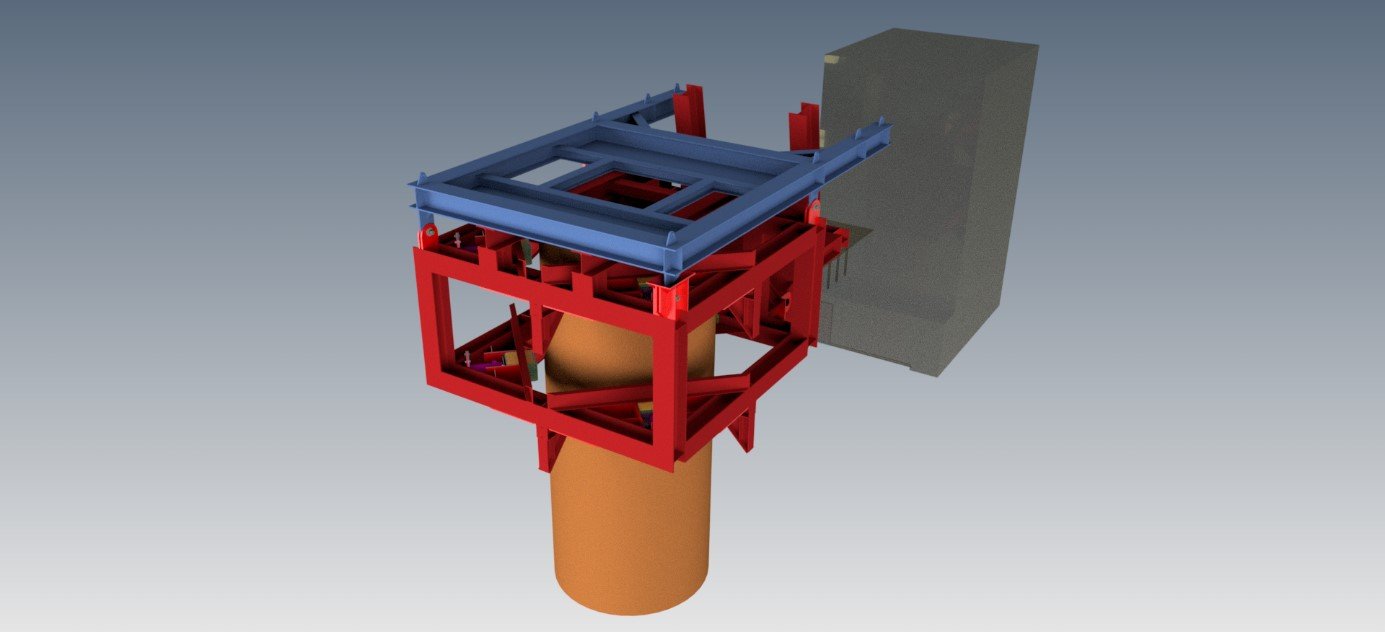

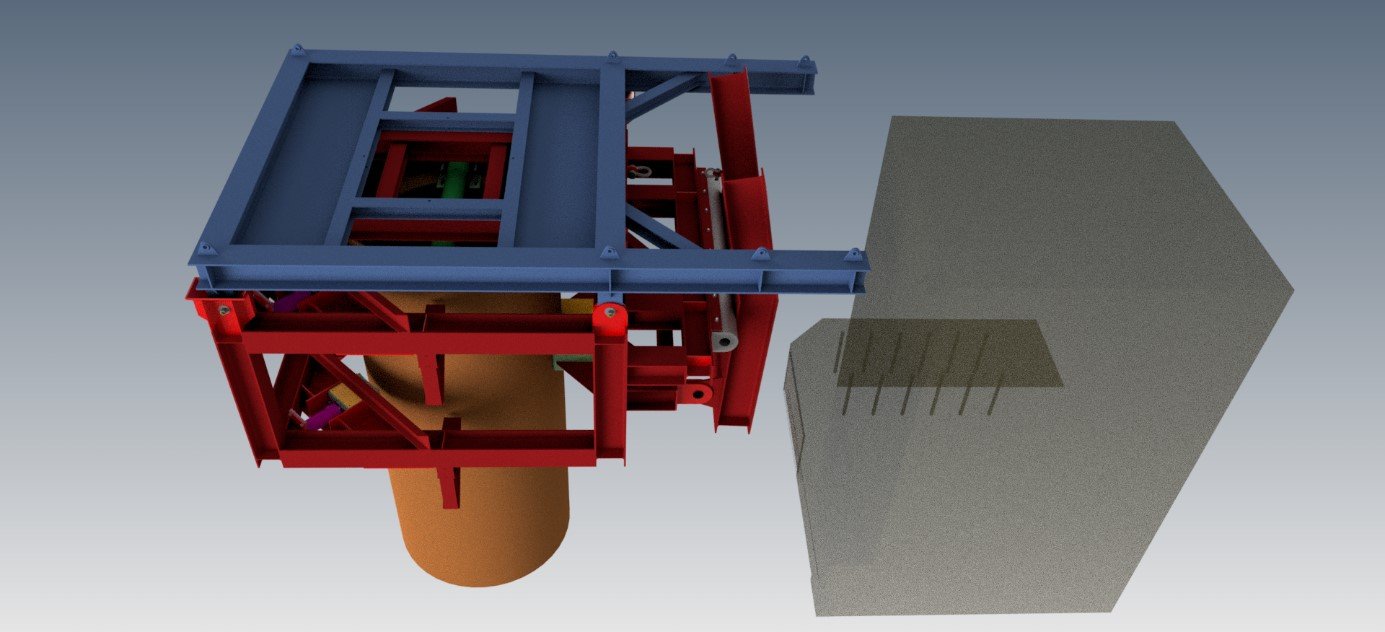

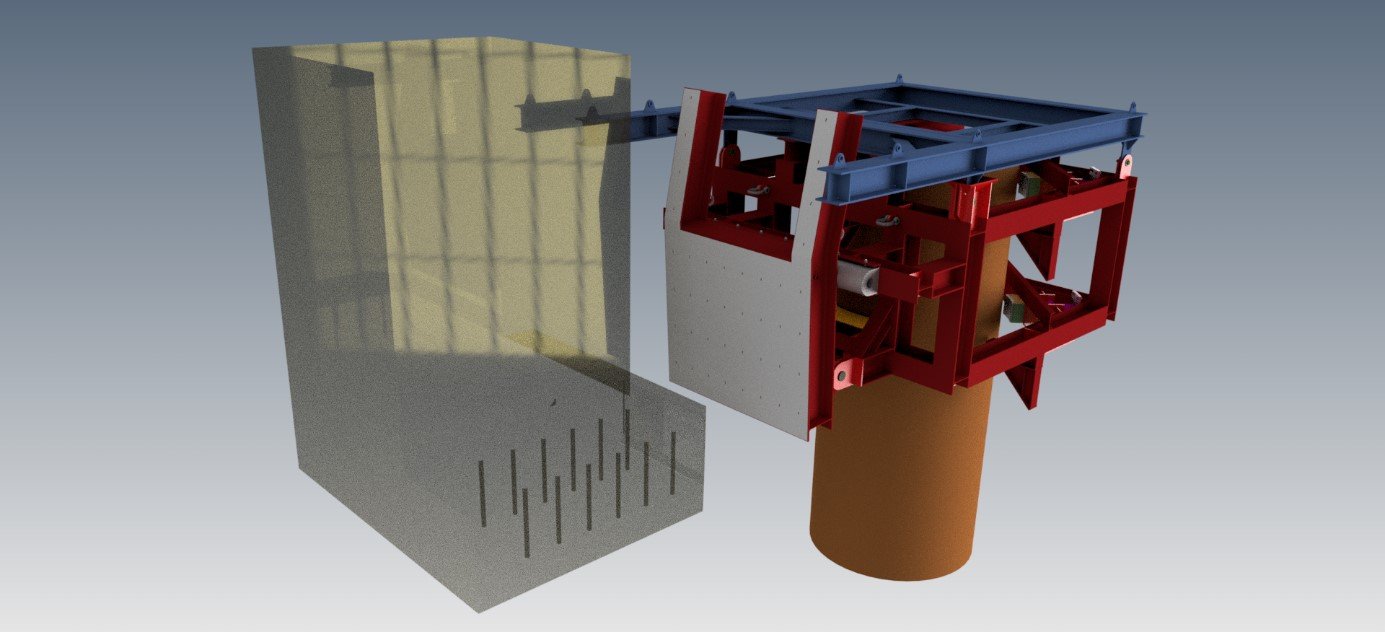

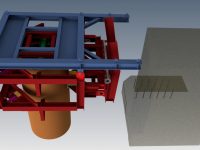

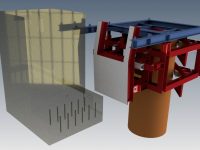

Per caisson, the positioning system consists of 4 guiding frames placed over piles on the seabed and 4 hydraulic cylinders which are mounted on the toe of the caissons. The guiding frame is a steel frame with a large sliding surface and is clamped on the pile slightly above the seabed with the use of hydraulic cylinders. The sliding surface is connected to the frame using hinges at the bottom and at the top of the sliding surface with a D-fender to absorb the impact energy of the caisson. The hydraulic cylinders on the toe of the caissons will push against the sliding plate to move the caisson into the correct location, when it is slightly above the seabed. The designs of the housings of the hydraulic cylinders were also part of the scope of MH Poly.

The placement tolerances of the caissons were very tight. This meant the tolerances of the placement of the guiding frames were tight too. For this reason, special frames were designed to guide the guiding frames into the correct heading during placement. These heading frames were placed inside the piles. For the lifting operations, a special lifting frame was designed which was able to install the heading frames and guiding frames.

The challenges in this project had to do with the dimensions. It was the size of the caissons which needed to be maneuvered as well as the dept of the positioning system. The dept to which the guiding frames needed to be placed made it necessary to design solutions to make placement possible with small tolerances so that the placement of the caissons became also possible within the strict placement tolerances. Due to a great collaboration with the team of Strukton Immersion Projects, we were able to come up with a solution for every challenge.

Strukton Immersion Projects was able to place the caissons well within the placement tolerances with the use of this positioning system. The caissons were placed only 1 centimeter of target!

More about the Çanakkale suspension bridge:

Locatie

Turkey

Opdrachtgever

Strukton Immersion Projects

Delen